An Essential Reference for Excavator Replacement Parts

Spare parts are crucial for ensuring that your excavator operates efficiently and safely. With regular use, components inevitably experience wear and tear, making it essential to replace them in a timely manner to sustain optimal performance. Selecting the appropriate spare parts for your excavator is key to guaranteeing reliability and minimizing downtime. High-quality components not only improve operational efficiency but also help lower long-term maintenance expenses. By opting for compatible and durable parts, you can significantly extend the lifespan of your machine and prevent unexpected breakdowns during critical operations.

Jun 17,2025

Spare parts are crucial for ensuring that your excavator operates efficiently and safely. With regular use, components inevitably experience wear and tear, making it essential to replace them in a timely manner to sustain optimal performance. Selecting the appropriate spare parts for your excavator is key to guaranteeing reliability and minimizing downtime. High-quality components not only improve operational efficiency but also help lower long-term maintenance expenses. By opting for compatible and durable parts, you can significantly extend the lifespan of your machine and prevent unexpected breakdowns during critical operations.

Understanding Excavator Types and Their Spare Parts Needs

Excavators play a crucial role in various sectors, including construction and mining. Each type of excavator boasts distinct characteristics and specific requirements for spare parts. Recognizing these differences is essential for optimizing your machine's performance and prolonging its operational lifespan.

Common Excavator Types

Crawler Excavators and Their Spare Parts

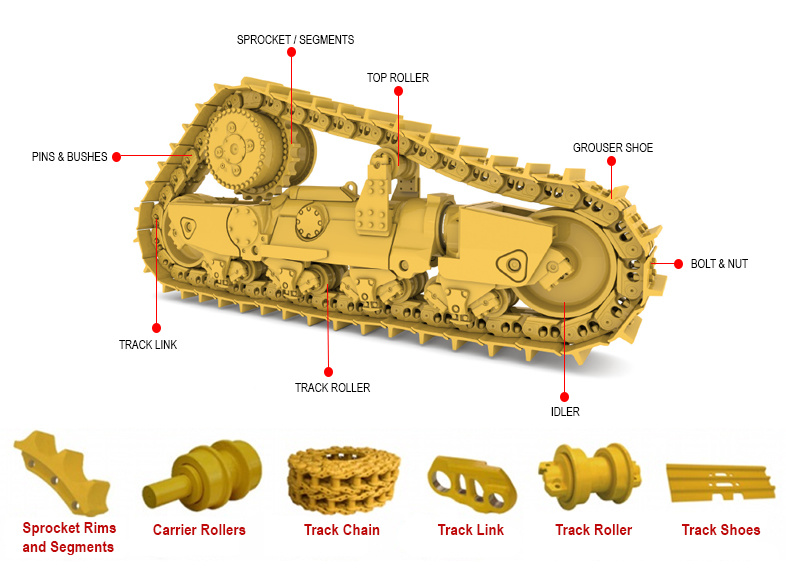

Crawler excavators are widely used for heavy-duty operations in construction and mining. Their tracks provide stability on rugged terrain, making them ideal for digging and lifting tasks. Key spare parts for crawler excavators include track and undercarriage components such as rollers, sprockets, and idlers. Regular maintenance of these parts ensures smooth equipment operation and prevents costly downtime.

Wheeled Excavators and Their Spare Parts

Wheeled excavators are versatile machines designed for urban construction projects. Compared to crawler excavators, they offer faster travel speeds on paved surfaces. Essential spare parts for wheeled excavators include tires, axles, and hydraulic components. Replacing worn tires and maintaining the hydraulic system keeps your machine ready for various tasks.

Mini Excavators and Their Spare Parts

Mini excavators are compact and efficient, making them perfect for small construction or landscaping projects. Their small size allows them to operate effectively in confined spaces. Spare parts for mini excavators typically include hydraulic hoses, bucket teeth, and engine components. Regular inspection and replacement of these parts ensure optimal performance in tight areas.

Long-Reach Excavators and Their Spare Parts

Long-reach excavators excel in operations requiring extended working ranges, such as dredging or demolition. Their extended booms and arms require specialized spare parts like hydraulic cylinders and seals. Maintaining these components is crucial for handling heavy loads and achieving precise operation.

How Excavator Type Affects Spare Part Needs

The type of excavator you use directly affects the spare parts you require. For example, crawler excavators need robust undercarriage components to handle rough terrain, while wheeled excavators rely on durable tires for mobility. Mini excavators require compact and efficient parts to fit their smaller frames. Long-reach excavators depend on high-quality hydraulic systems to support their extended arms.

By understanding the specific needs of your excavator, you can stock the right spare parts to minimize downtime. This proactive approach ensures your machines remain reliable, whether you're working on a construction site or a mining project.

Excavator Wear Parts

Excavators experience constant wear during operation. Regularly replacing these parts helps maintain their functionality.

Bucket Teeth and Adapters

Bucket teeth and adapters bear the brunt of digging and loading tasks. These parts wear out quickly, especially under harsh conditions. Replacing them ensures efficient digging and reduces stress on other components.

Cutting Edges and Blades

Cutting edges and blades are crucial for grading work. Dull or damaged blades reduce precision and increase fuel consumption. Regular replacement ensures your machine maintains peak performance.

Tracks and Undercarriage Components

Tracks and undercarriage components (such as rollers and sprockets) support the excavator's mobility. These parts endure significant stress, particularly on rough terrain. Maintaining them prevents operational delays and extends machine lifespan.

Focusing on these essential excavator spare parts ensures your machine remains reliable and efficient. Regular inspections and timely replacements not only enhance performance but also reduce long-term maintenance costs.

Excavator Safety and Control Components

Safety and control components are vital for ensuring smooth operation and operator safety. They protect the operator while improving precision and reliability during demanding tasks. Regular maintenance and prompt replacement significantly boost excavator performance.

Stabilizer Cylinders

Stabilizer cylinders play a critical role in preventing accidents. They provide stability and control, especially when handling heavy loads or operating on uneven terrain. Over time, seals and internal mechanisms may wear due to frequent use. Replacing worn stabilizer cylinders ensures stability and safety in challenging conditions.

Pro Tip: Always check stabilizer cylinders for leaks or performance degradation. Early detection prevents costly repairs and ensures operator safety.

Control Levers and Joysticks

Control levers and joysticks are the primary interface between you and the excavator. Whether digging, lifting, or grading, they enable precise machine manipulation. Frequent use causes wear, affecting responsiveness. Replacing damaged or sluggish controls restores smooth operation and enhances control.

Key Features of Quality Levers/Joysticks:

Durable construction for long-term use

Ergonomic design for operator comfort

High sensitivity for precise movements

How to Choose the Right Spare Parts for Your Excavator

Compatibility with Your Excavator Model

Always ensure selected parts are compatible with your excavator model. Incompatible parts may cause performance issues or machine damage. Verify part specifications against your excavator's requirements. For example, when replacing safety control levers for a Caterpillar excavator, confirm they match the model's design and function. Compatibility guarantees smooth installation and optimal performance.

Pro Tip: Refer to your excavator manual for compatible parts. This step saves time and prevents costly errors.

OEM (Original Equipment Manufacturer) vs. Aftermarket Parts

When choosing excavator parts, you’ll encounter two main options: OEM parts and aftermarket parts. OEM parts are made by the original manufacturer, ensuring perfect fit and high quality. Aftermarket parts are produced by third-party companies and often cost less. While OEM parts offer reliability, aftermarket parts can be cost-effective if sourced from reputable suppliers like Yongsheng Machinery. Assess your needs and budget to decide.

| OEM Parts Advantages | Aftermarket Parts Advantages |

|---|---|

| Guaranteed compatibility | Cost-effective |

| Premium materials | Wide availability |

| Manufacturer warranty coverage | Suitable for non-critical components |

Cost vs. Quality Trade-off

Balancing cost and quality is critical when selecting excavator parts. Low-priced parts may seem attractive but often compromise durability and performance. Investing in high-quality components reduces frequent replacement needs and ensures long-term efficiency. For critical systems (e.g., hydraulics or engine), prioritize quality over cost. For less critical parts, explore affordable options without sacrificing reliability.

Did You Know? High-quality parts extend your excavator’s lifespan and reduce downtime, saving you money long-term.

Secrets to Making Informed Decisions

Consult Your Excavator Manual

Your excavator manual is invaluable for part selection. It provides detailed specifications, part numbers, and maintenance guidelines. For instance, when replacing hydraulic hoses, the manual specifies correct dimensions and pressure ratings.

Seek Advice from Industry Professionals

Mechanics or suppliers can offer crucial insights for choosing optimal parts. They recommend reliable brands, identify common issues, and guide installation. Reputable suppliers like Yongsheng Machinery provide expert support to ensure correct choices.

Expert Tip: Always ask about part performance, warranties, and compatibility. Experienced suppliers address your concerns for guaranteed satisfaction.

Evaluate Brand/Supplier Reputation (e.g., Yongsheng Machinery)

A brand/supplier’s reputation is essential for part quality. Look for suppliers with positive reviews, certifications, and proven industry track records. Yongsheng Machinery, for example, has over 20 years of experience providing high-quality parts for construction and mining equipment. Their commitment to quality and customer satisfaction makes them a trusted choice.

When choosing a supplier, prioritize:

Transparent product descriptions

Warranty and after-sales support

Positive customer feedback

Following these guidelines ensures your excavator stays efficient and reliable, minimizing downtime and maximizing productivity.

Ensuring Quality and Reliability of Excavator Spare Parts

Securing part quality and reliability is critical for maintaining excavator efficiency. Choosing trusted suppliers, conducting thorough inspections, and securing solid warranties minimize downtime and extend machine longevity.

Finding Reliable Excavator Parts Suppliers

Research Supplier Reviews and Ratings

Start by researching supplier reviews and ratings. Customer feedback reveals reliability and product quality. Seek consistent positives like on-time delivery, durable parts, and excellent service. Avoid suppliers with frequent complaints about defects or poor support.

Tip: Use online platforms/forums where industry professionals share supplier experiences to identify reliable sources.

Check Certifications and Industry Standards

Certifications (e.g., ISO) indicate a supplier’s commitment to quality. Compliance ensures parts meet stringent requirements, enhancing excavator reliability.

Did You Know? Certified suppliers often provide parts meeting or exceeding OEM standards.

Quality Inspection of Excavator Parts

Check Materials and Workmanship

Inspect materials and craftsmanship before purchase. High-quality materials (e.g., durable metals, reinforced rubber) withstand harsh conditions. Examine surfaces and structures for flaws like uneven finishes or weak joints.

Pro Tip: Request detailed product specifications to verify part quality and suitability.

Performance and Durability Testing

Testing part performance/durability is essential. Reliable parts must operate seamlessly under heavy loads/extreme conditions. Request performance test results/certifications when possible.

Logical Insight: Quality parts minimize downtime and ensure consistent performance, boosting project productivity.

Securing Warranties and Support for Excavator Parts

Importance of Warranty Coverage

Warranties protect your investment. Comprehensive coverage ensures free replacement/repair of defective parts. Choose suppliers with clear, fair warranty terms and reasonable coverage periods for critical components.

Recommendation: Always review warranty policies before purchase. Ensure coverage for defects and performance issues.

Availability of After-Sales Support

After-sales support resolves issues swiftly. Reliable suppliers offer technical assistance, installation guidance, and prompt responses.

Key Point: Suppliers like Yongsheng Machinery provide extensive after-sales support, including expert advice and rapid shipping to keep your excavator operational.

Prioritizing inspections, certified suppliers, and strong warranties maintains excavator efficiency/reliability, reduces long-term costs, and ensures peak machine performance.

Yongsheng Machinery: Your Trusted Partner for Excavator Undercarriage Parts

Why Choose Yongsheng Machinery's Excavator Undercarriage Parts

Yongsheng Machinery is a trusted supplier of excavator undercarriage parts. With over 20 years of experience, the company is renowned for providing high-quality components that meet or exceed industry standards.

The undercarriage is the foundation for stable excavator operation, and its durability and reliability directly impact the machine's overall operational efficiency and safety. Yongsheng Machinery offers a comprehensive range of undercarriage parts, including track assemblies (track links, track shoes, track bolts), carrier rollers, track rollers, guide wheels (idlers), and tensioning devices. These parts are manufactured using premium wear-resistant materials and advanced processes, ensuring exceptional longevity and performance even in harsh working conditions. Choosing Yongsheng Machinery allows you to significantly reduce undercarriage system failure rates, minimize unplanned downtime, and extend the overall service life of your excavator.

Pro Tip: Regularly inspecting and replacing worn parts with Yongsheng Machinery's high-quality undercarriage components is key to maintaining stable, efficient equipment operation and lowering long-term maintenance costs.

Yongsheng Machinery also provides both OEM and aftermarket options, offering flexibility to suit your budget and specific needs. Its aftermarket parts are manufactured strictly to OEM standards, ensuring perfect compatibility and reliability comparable to genuine parts. This makes Yongsheng Machinery a solid partner for maintaining your excavator's undercarriage system performance.

The Role of Yongsheng Machinery Undercarriage Parts in Ensuring Operational Efficiency and Safety

The excavator undercarriage system bears the entire machine's weight and provides traction and stability on various complex terrains; its condition is paramount. The range of undercarriage parts offered by Yongsheng Machinery is designed to enhance your excavator's mobility, stability, and operational efficiency in demanding environments.

Yongsheng Machinery's undercarriage parts (such as high-wear-resistant track shoes, heavy-duty carrier rollers, and guide wheels) are renowned for their exceptional durability, precise fit, and excellent impact resistance. They effectively distribute loads, reduce abnormal wear, and protect the undercarriage structure from damage. This ensures your excavator maintains smooth, efficient operation and operator safety even under heavy loads on rough, uneven, muddy, or rocky terrain.

Did You Know? Selecting Yongsheng Machinery's high-quality undercarriage parts can significantly reduce the risk of failures like track derailment and roller damage, saving valuable repair time and costly downtime.

The company also offers customization services to meet your unique requirements. Whether you need undercarriage parts for specific operating conditions (such as extreme cold, mining, wetlands) or for special excavator models, Yongsheng Machinery can provide tailored solutions based on your specific needs. Their rigorous commitment to quality ensures every undercarriage part contributes solidly to the machine's overall performance, safety, and durability.

How Yongsheng Machinery Ensures the Quality and Reliability of Undercarriage Parts

Yongsheng Machinery consistently prioritizes product quality and reliability, a commitment embedded throughout the production process of all its undercarriage parts. The company implements a stringent quality inspection system, ensuring every component meets high standards from raw materials to the finished product. Every step of the manufacturing process – material selection, forging/casting, heat treatment, precision machining, and final assembly – is strictly monitored and tested.

You can rely on Yongsheng Machinery's undercarriage parts to deliver consistent, stable performance even under high-impact, high-wear, heavy-load harsh conditions. They strictly adhere to industry certifications, ensuring products meet or exceed OEM specifications. This relentless pursuit of quality gives you confidence in the reliability and service life of their undercarriage parts.

Key Insight: Choosing a supplier like Yongsheng Machinery that meets and exceeds recognized industry standards is fundamental to ensuring the stable, efficient, and safe operation of your excavator's undercarriage system.

Yongsheng Machinery also provides comprehensive warranty coverage for its products. This protection safeguards your investment and provides peace of mind. Furthermore, the company offers outstanding after-sales support, including professional technical consultation and efficient logistics. This ensures you quickly receive the needed undercarriage parts, minimizing equipment downtime and keeping your engineering projects on schedule.

Partnering with Yongsheng Machinery means you gain access to high-quality excavator undercarriage parts, professional after-sales support, and reliable service guarantees. This makes Yongsheng Machinery the ideal partner for maintaining your excavator's operational efficiency, safety, and overall longevity.

Understanding and selecting the right excavator undercarriage parts is crucial for ensuring efficient and safe equipment operation. High-quality undercarriage components ensure continuous stable traction and support, reduce downtime caused by unexpected failures, and significantly extend the machine's service life. Whether you are in construction, earthmoving, mining, or forestry, a reliable undercarriage system is the foundation for equipment to tackle various demanding challenges. Yongsheng Machinery provides trusted undercarriage solutions, including high-wear-resistant track assemblies, heavy-duty carrier rollers, guide wheels, and tensioning devices, flexibly adaptable to your specific operating conditions and machine model requirements. Choosing Yongsheng Machinery is a wise investment in your equipment's foundational performance, safety, reliability, and long-term return on investment, ensuring your excavator moves forward steadily and performs at its best in every project.

Frequently Asked Questions

What are the benefits of using OEM undercarriage parts for excavators?

OEM (Original Equipment Manufacturer) undercarriage parts ensure compatibility and reliability. These components perfectly match your excavator’s specifications, delivering optimal performance. High-quality OEM undercarriage parts (e.g., track links, track rollers, idlers) enhance the durability of your undercarriage system and reduce the risk of unexpected failures (e.g., track derailment, roller damage). Choosing OEM undercarriage parts minimizes downtime and maintenance costs, boosting overall project productivity.

Tip: While OEM undercarriage parts may have a higher upfront cost, they save money long-term by avoiding frequent repairs and replacements.

How do I verify if an undercarriage spare part is compatible with my excavator?

Refer to your excavator manual for detailed specifications and part numbers. Match these details to the undercarriage spare part you intend to purchase. Consult suppliers or manufacturers for guidance. Reliable suppliers like Yongsheng Machinery offer expert support to ensure you select the correct undercarriage parts (e.g., compatible track link models, roller specifications).

Pro Tip: Before purchasing undercarriage spare parts, always verify your excavator’s model and serial number. This step guarantees seamless fitment and functionality.

Why is regular maintenance of excavator undercarriage parts important?

Regular maintenance prevents minor wear from escalating into major issues, ensuring your excavator operates efficiently and safely. Timely replacement of worn undercarriage components (e.g., severely worn track shoes, failed rollers) reduces failure risks and workflow disruptions. Maintenance also extends the lifespan of your undercarriage system and entire machine, saving costly repair or replacement expenses.

Did You Know? Neglecting undercarriage maintenance can reduce travel efficiency, increase fuel consumption, and compromise equipment stability—impacting project safety and profitability.

What should I prioritize when purchasing aftermarket undercarriage parts?

Prioritize quality and reliability. Choose parts that meet or exceed OEM standards. Opt for reputable suppliers like Yongsheng Machinery, renowned for high-quality aftermarket undercarriage solutions (e.g., wear-resistant track shoes, heavy-duty rollers). Check customer reviews and certifications (e.g., material reports) to ensure durability and compatibility with your excavator’s undercarriage system.

Key Insight: High-quality aftermarket undercarriage parts (like those from Yongsheng Machinery) offer cost-effective solutions without compromising performance or longevity.

How can I extend the service life of my excavator’s undercarriage system?

To maximize undercarriage lifespan:

Inspect regularly for wear/damage (track link wear, roller/roller rotation, idler condition, track shoe wear).

Replace critical parts promptly (e.g., worn track links/shoes, failed rollers, aged track bolts).

Use high-quality spare parts from trusted suppliers like Yongsheng Machinery.

Follow maintenance schedules (cleaning, lubrication, tension adjustments) in your excavator manual.

Train operators to avoid sharp turns on extreme terrain or prolonged uneven loading, reducing abnormal impact on the undercarriage.

Logical Insight: Consistent maintenance and premium undercarriage parts minimize abnormal wear, ensuring years of reliable travel system performance and lower operating costs.

What signs indicate that undercarriage parts (e.g., rollers, idlers) need replacement?

Common failure signs include:

Track rollers/idlers: Stiff rotation, seizing, abnormal noises (squeaking/grinding), oil leaks, seal failure, severe rim wear, or breakage.

Track links/shoes: Excessive wear (height below standard), cracks, fractures, loose/broken track bolts.

Idlers: Severe rim wear, excessive wobble, rotation noises, oil leaks.

Overall travel: Track derailment, deviation during travel, abnormal vibrations, loss of traction.

Tensioning devices: Inability to maintain track tension, oil leaks.

Recommendation: Replace affected undercarriage parts immediately to avoid system damage or downtime. Regularly inspect high-wear components to detect issues early.

How do I choose a reliable excavator undercarriage parts supplier?

A reliable supplier should have:

Positive customer reviews/ratings for undercarriage parts.

Industry-standard certifications (e.g., ISO, material certifications).

Comprehensive warranties covering undercarriage components.

Professional after-sales support, including technical assistance (e.g., part selection, installation guidance).

Suppliers like Yongsheng Machinery excel in these areas, delivering high-quality undercarriage parts and exceptional service.

Tip: Research industry forums and professional networks for trusted undercarriage-focused suppliers.

What role does a warranty play when purchasing undercarriage parts?

A warranty protects your investment in expensive undercarriage components (e.g., track groups, roller assemblies) by covering manufacturing defects or performance issues. A strong warranty ensures free replacement/repair of faulty parts. Always review warranty terms (coverage scope, duration) before purchase—especially critical for high-wear parts.

Key Point: Suppliers like Yongsheng Machinery offer robust warranties, demonstrating confidence in their undercarriage products and providing customer peace of mind.

Can aftermarket undercarriage parts perform as well as OEM parts?

Yes, high-quality aftermarket undercarriage parts from reputable suppliers like Yongsheng Machinery can match or exceed OEM performance. These parts use premium wear-resistant materials (e.g., specialty alloy steel) and strict manufacturing processes to meet OEM standards for durability and reliability. They also offer cost competitiveness without sacrificing quality.

Did You Know? Yongsheng Machinery’s aftermarket undercarriage parts—like wear-resistant track shoes and heavy-duty rollers—are renowned for compatibility and long-term performance.

How can I minimize downtime caused by undercarriage part failures?

To reduce undercarriage-related downtime:

Stock critical spare parts: Maintain inventory for high-wear items (track shoes, rollers, track bolts).

Inspect regularly: Follow scheduled checks to detect issues early (e.g., near-limit track link wear, roller noises).

Partner with reliable suppliers: Choose suppliers like Yongsheng Machinery for fast shipping and technical support (e.g., urgent part selection).

Use high-quality parts: Reduce failure risks and ensure stable undercarriage operation.

Schedule preventive maintenance: Replace wear parts during off-peak periods to avoid workflow disruption.

Pro Tip: Establish long-term partnerships with suppliers for prioritized support and supply guarantees.

PREVIOUS:

NEXT:

Related Posts

How Should The Supporting Wheels Be Selected To Avoid Stepping On Thunder?

High-quality support wheels mainly depend on the performance of its steel. The material of the roller body is generally 50Mn, 40Mn2, (MN: synonymous with the element of manganese).

Carrier Wheels Are Suitable For Various Models At Home And Abroad

Sprocket wheels are mainly used in various crawler bulldozers, excavators, pavers, milling machines, rotary drilling rigs or other crawler machinery equipment at home and abroad.

Contact Us

E-mail :

sales@china-ysm.com

Phone/WhatsApp:

+86-18606961587

Address:

No.8 Binjiang Street, Binjiang Industrial Zone, Xiamei Town, Nan An City, Quanzhou City, Fujian Province, China